Special Bonding Service

|

Bonding type |

Process Description |

Process accuracy |

Support size |

|

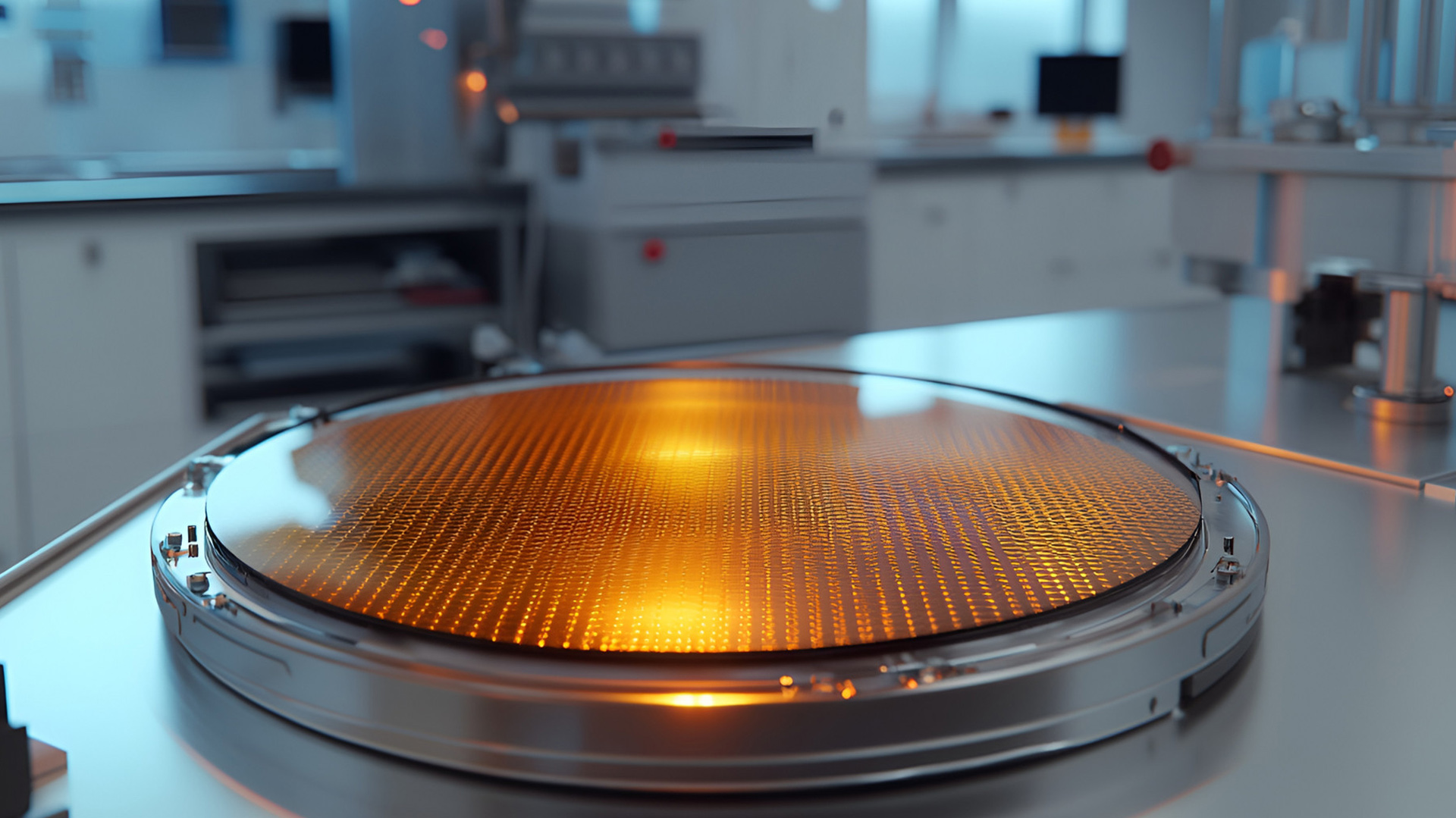

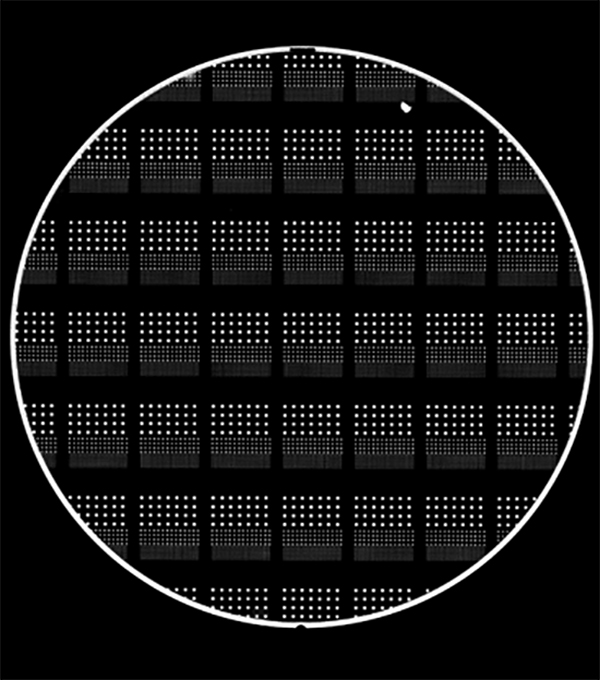

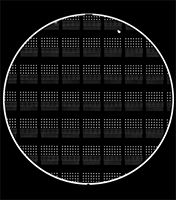

Cavity bonding |

By bonding at room temperature and pressure, the cavity bonding process can be achieved, with no voids in the effective area of the chip |

Void ratio: ≤ 1% |

8 inches/12 inches |

|

Heterogeneous bonding |

YCMEC utilizes special processes to solve heterogeneous bonding problems and is suitable for products of different sizes |

- |

2-inch/6-inch/8-inch |

|

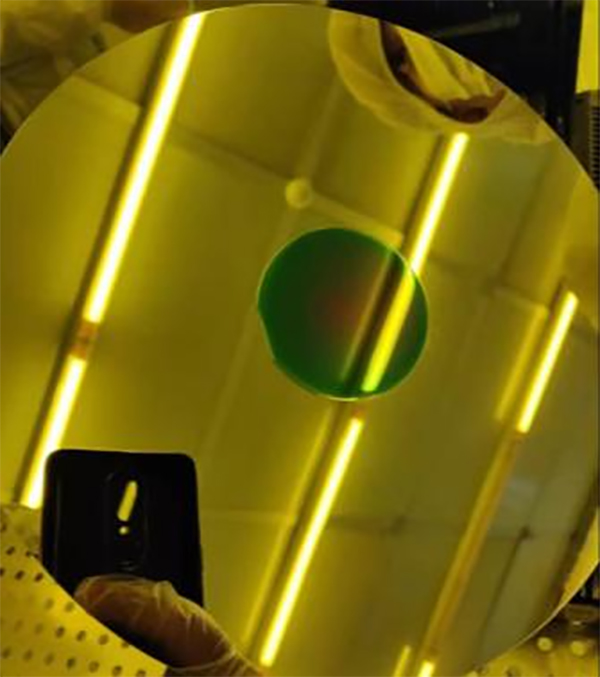

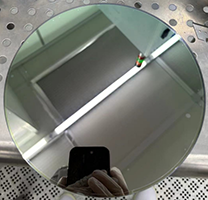

Quartz-Si bonding |

By preparing an anti reflective film on the surface of quartz and subsequent bonding processes, high transmittance and high-precision bonding of quartz can be achieved |

Transmittance rate: ≥ 95% |

8 inches |

|

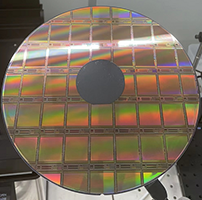

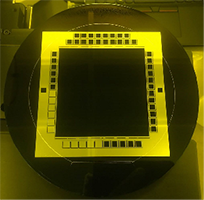

6-inch bonding |

Using special fixtures to achieve automatic processing of 6-inch wafers, including surface treatment, 6-inch/8-inch bonding, thinning, ARC, and pad open processes |

- |

6 inches/8 inches |

|

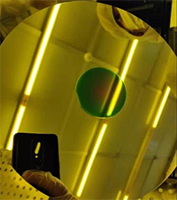

Glass bonding |

According to customer requirements, patterns are prepared on the glass surface through special processes, and bonding, thinning, and subsequent pattern production are completed |

Bonding accuracy:3σ≤500nm |

8 inches |

|

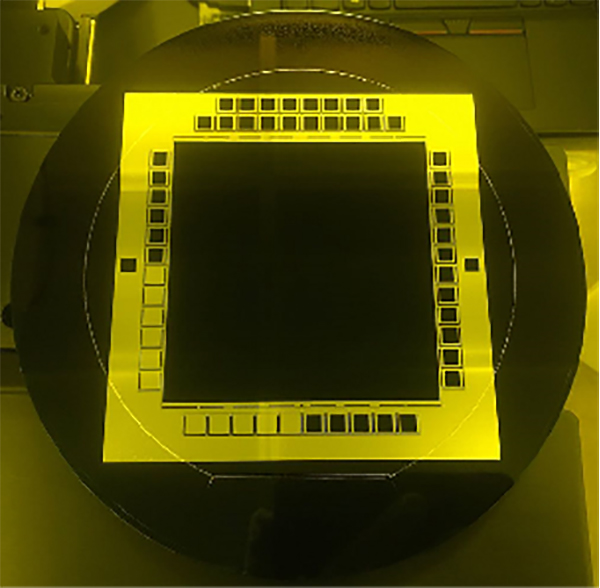

D2W bonding |

By utilizing pick-and-place and bonding processes, high-precision Co-D2W bonding has been achieved, improving the utilization rate of die |

Final alignment accuracy:3σ≤2um |

8 inches |

|

|

|

|

|

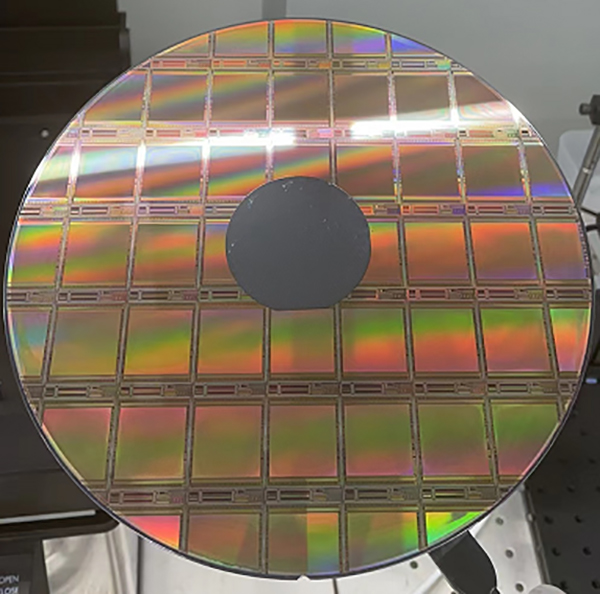

| 2-inch+8-inch bonding | Cavity bonding | Quartz and silicon bonding | 6-inch+8-inch bonding | 3-inch+12 inch bonding |